Medications are Becoming Part of the Technical Fabric of the Pharmacy

- The last 30 years of innovation have brought us dispensing cabinets, infusion pumps, the eMAR and CPOE, but each breakthrough added complexity, process and new workflows.

- Harmonizing, enabling and coupling these systems without adding new tasks, expertise or cost is the best opportunity to unlock value for the pharmacy and pharmaceutical manufacturers.

How Your Customers are

Thinking About Innovation

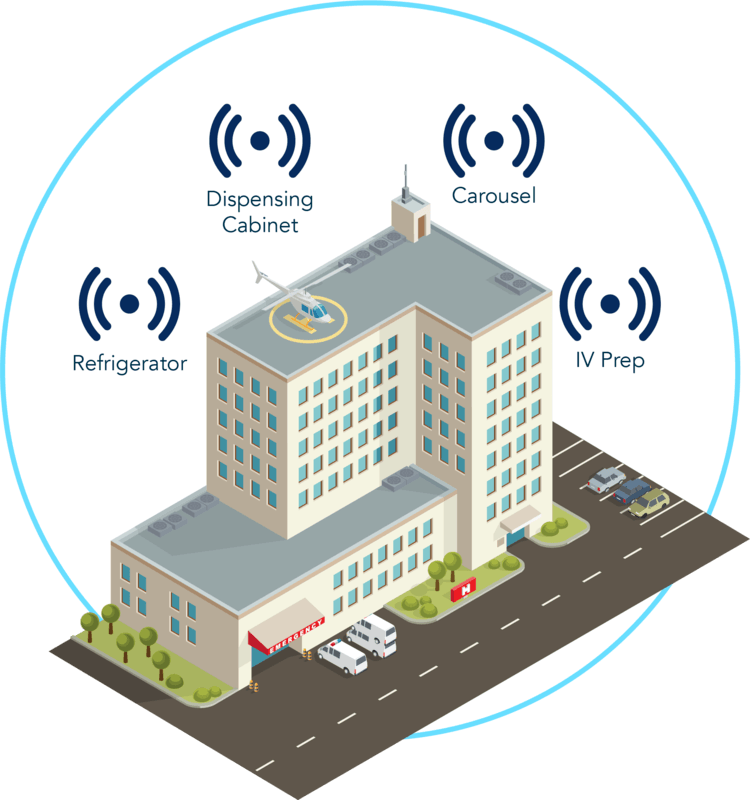

“I want this under my compounding hood. I want this in my carousel. I want to just walk away from the ADC when it’s stocked because it just knows. Kit Check is one thing, but the RFID system and the data – that’s infrastructure I need for everything.”

“I don’t want you guys to make another thing for me. I want you to help me with the big picture that fixes all of the stuff I already have.”

“I want this for OR, obviously. But I really want this at bedside, because there’s a whole lot of business processes that could be conducted instantaneously at administration. Not just safety, but billing, 340B, you name it.”

See the need and opportunity for integration!

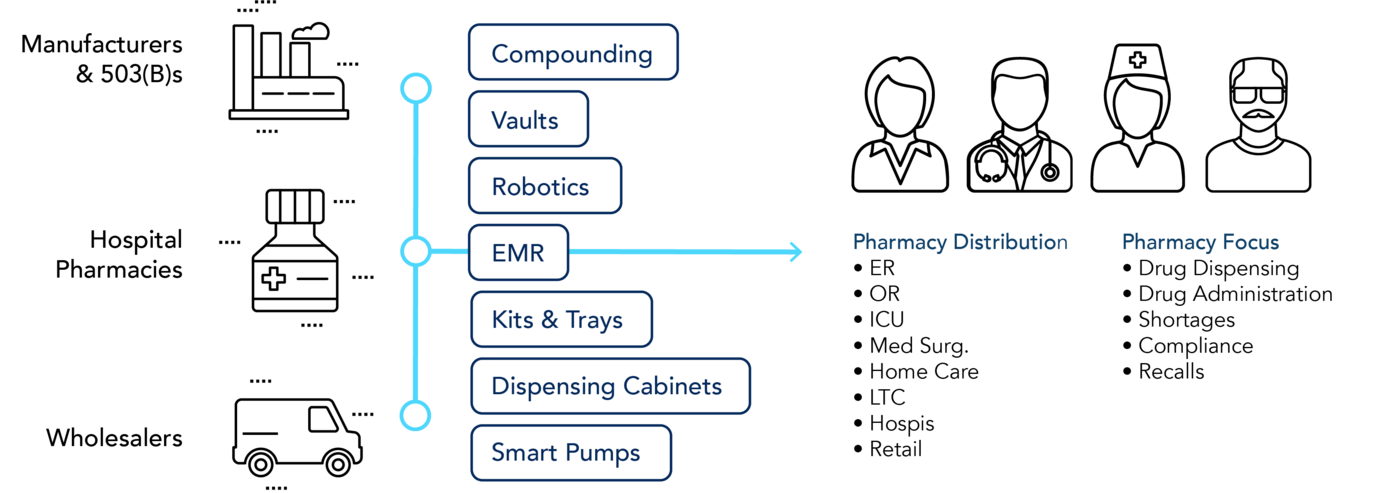

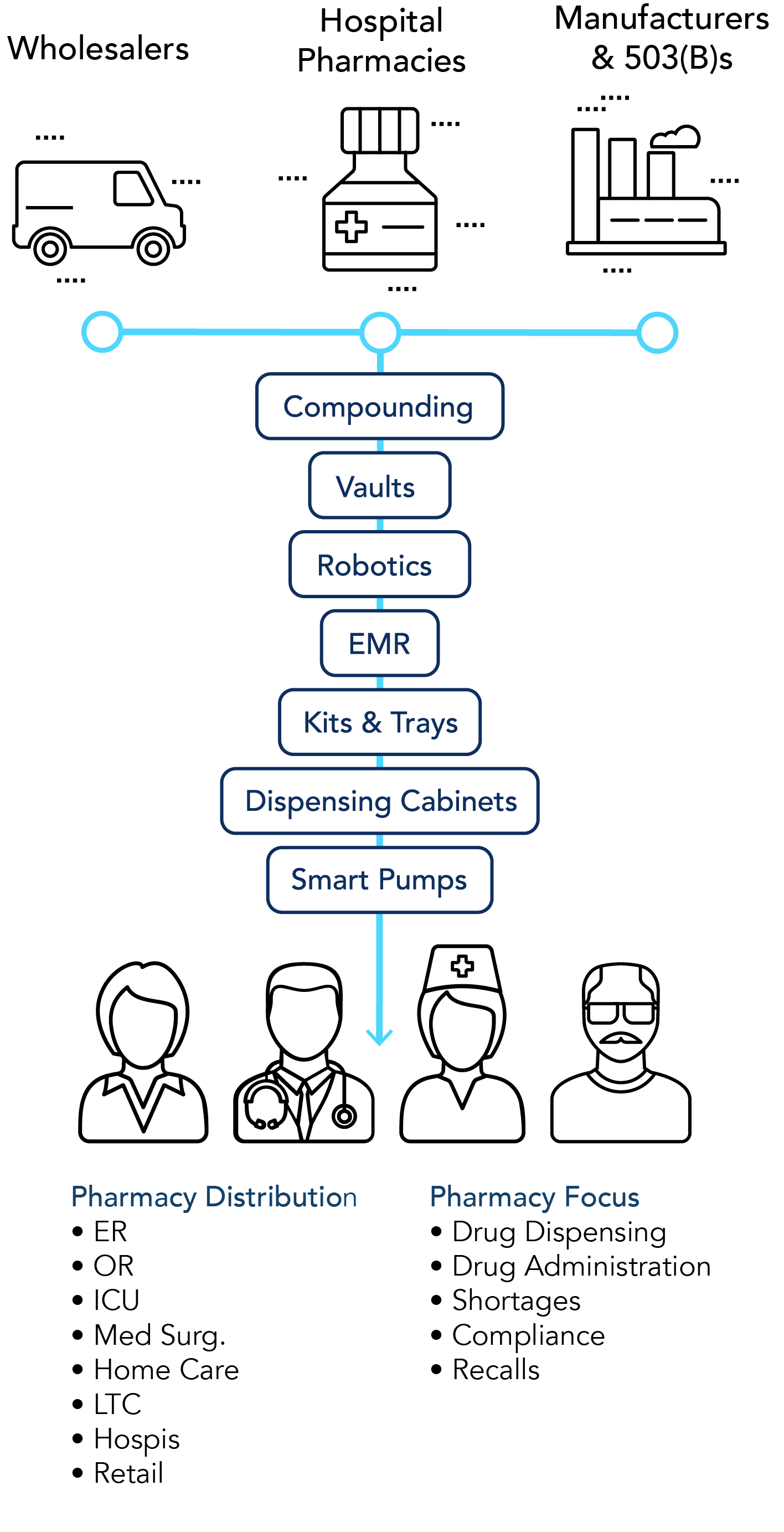

The Evolving Pharmaceutical Ecosystem

Kit Check has developed a software solution that provides connectivity and visibility across the entire pharmaceutical ecosystem, from manufacturing facility to the hospital.

One solution that connects existing and emerging dispensing systems, work flows and data throughout a product’s dynamic lifecycle giving a complete picture of the life of a unit dose.

The Works with Kit Check Solution

The Works with Kit Check certification is a mark of trust and compatibility with Kit Check and other leading automation vendors (carousels and ADMs).

Works with Kit Check Certification

- An elevated-standard in RFID certification specifically developed for the evolving pharmaceutical ecosystem.

- Assures manufacturers tags perform optimally in customer and partner applications.

- Enables manufacturers, service providers, and technology vendors to differentiate their offerings with Kit Check’s partners and community of over 500 hospital customers.

White Glove Service

Using cGMP processes, we manage the entire installation and certification process from plan development to final line testing. We apply our solution with minimal impact to your line, your speed, your yield. We understand that revalidation is a painstaking process.

Access to the Bluesight Platform

A robust database containing all critical item-level drug data that provides:

- Lifecycle data

- Product expiration, recall and shortage data

- Business insights (to optimize portfolios and gain customer preference insights)

- DSCSA compliance information

- Sales tools

Developed for cGMP Environments

- Verification activities throughout the software development life cycle (SDLC)

- Ready for validation in your environment

- cGMP relevant data that can be trusted in downstream workflows throughout the supply chain

The Right RFID Tags

A portfolio of inlays that work best in the challenging hospital environment:

- We have collaborated with Avery Dennison, the world largest RFID partner, to develop tags and inlays that perform optimally in hospital settings

- Kit Check also accepts other tags that meet our elevated standard

Benefits Across the Pharmaceutical Ecosystem

We connect all of the elements in the pharmaceutical ecosystem that touch a product and make them smarter. You can see in real time, at the unit level, a product’s journey from the plant to the point of administration.

RFID inlays

Kit Check’s RFID inlays and tracking technology help to embrace the serialization trend, providing product visibility at a granular, unit of use level.

Bluesight Data Hub

We provide access to the Bluesight Data Hub for cGMP-relevant data to enable many downstream workflows and help manage recalls, returns, expiry, refrigeration and more.

Perform Optimally

The Kit Check solution assures manufacturer’s tags perform optimally in customer and partner applications, plus it enables manufacturers, service providers and technology vendors to differentiate their offerings with Kit Check’s partners and community of over 500 hospital customers.

Nephron is proud to implement Kit Check across all 503B syringes,” says Lou Kennedy, Chief Executive Officer, Nephron. “Kit Check made the process easy with minimal interruptions to our workflows. We believe this helps differentiate our products and will ultimately be the standard within our industry.

Nephron

The Solution Is Here

Entrenched players build barriers to easy data exchange with competitors. Most point solutions are mature and do their part well. Even solutions that could be transformed by technology have sales, marketing, implementation and account know-how that needs to be leveraged.

We see a need and an opportunity for integration and a cooperative partner to enable it. That’s Kit Check.

To schedule a meeting or learn more, please fill out this form.